What about the project

“BEATRICS” is a Research scientific project funded for 60 Months from the Italian Ministry of University and Research (MIUR), under the “Procedura per l’attuazione dell’intervento FARE Ricerca in Italia: Framework per l’attrazione e il rafforzamento delle eccellenze per la Ricerca in Italia”, annualità 2016”programme (Grant Agreement ID R16R7NLWPW).

The research project, started on January 14th 2018, is coordinated by Prof. Enrico Tronconi and hosted at Politecnico di Milano (Milan – IT) Department of Energy–Laboratory of Catalysis and Catalytic Processes.

Budget: € 291.070

State of the art

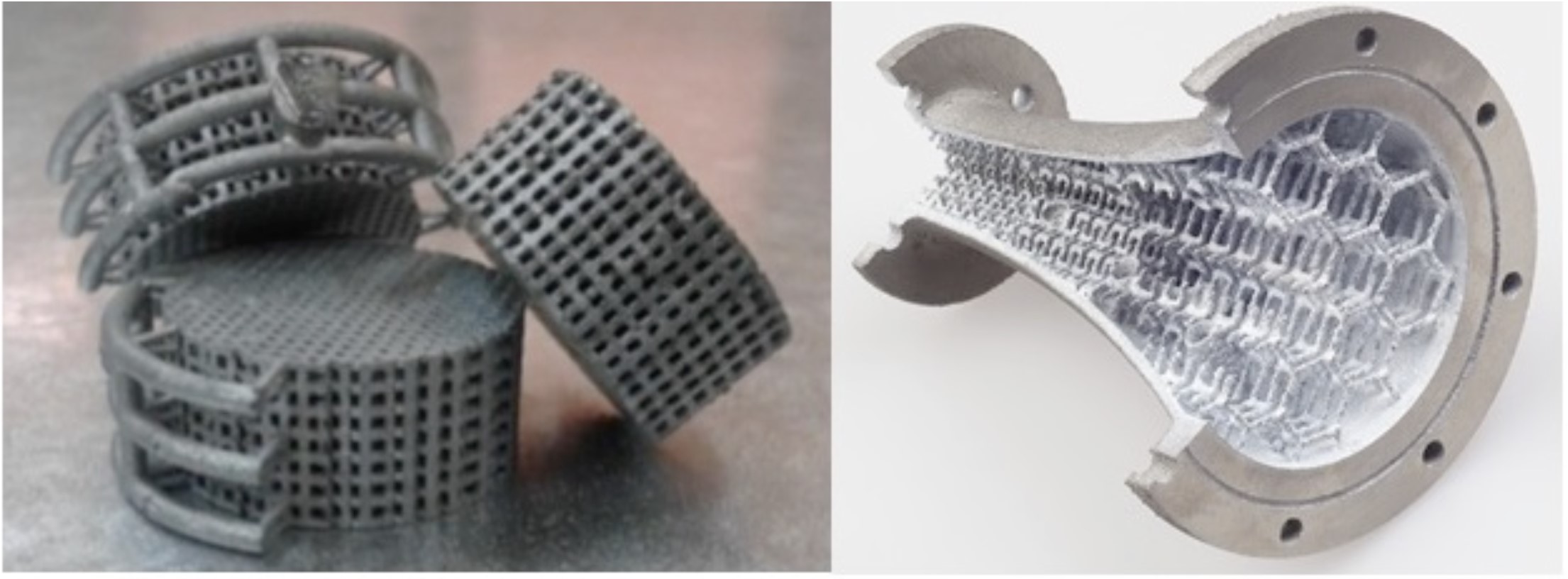

Many crucial heterogeneous catalytic reactions for emissions control have been run for decades in converters loaded with catalysts in the shape of washcoated honeycomb monoliths. A paradigm shift is now needed due to the requirements of the more and more stringent emissions legislations worldwide. A potential game-changing alternative is provided by substrates with open random or regular cellular microstructures, like open-cell foams (aka sponges) or periodic open cellular structures (POCS). Scattered work in the literature suggests that such structures grant substantially enhanced fluid-solid mass and heat transport properties.

Accordingly, they can optimize the trade-off between mass transfer and pressure drop, i.e. the critical performance index in many applications of Environmental Catalysis like e.g. the catalytic converters for vehicular Exhaust Aftertreatment Technologies (EAT). Furthermore, the dynamic response of highly void cellular microstructures is faster, and therefore more favorable than in the case of the conventional honeycombs, resulting e.g. in rapid cold-start transients due to the reduced thermal mass and to the more effective gas-solid heat transfer. Thus, the switch to microstructured substrates empowers substantially enhanced global performances, which can be exploited to design more efficient catalytic converters for the substantial reduction of polluting engine emissions.

Mail Goal of the project

The goal of the BEATRICS project is twofold:

- to fully exploit recent elucidation of fundamental and engineering properties of novel open cellular structured catalysts to investigate new concepts for their design, manufacturing, catalytic activation and operation (e.g. regular cellular structures with optimized geometries, production by 3D printing); to this purpose BEATRICS will combine advanced CFD modelling with lab- and pilot-scale experimentation in order to identify the optimal structure-performance relationship of novel cellular substrates, use such new knowledge to design optimized prototypes, apply unconventional additive manufacturing technologies for their production, and eventually test them at a representative scale in suitable converter units;

- to demonstrate their potential for a quantum leap in the intensification of the NH3-SCR process, a key technology for the control of NOx emission from Light and Heavy Duty Diesel vehicles, in the widest range of transient, realistic test conditions. While affecting also other research areas, the results of this multidisciplinary project will enable novel converter designs based on tuning geometry, materials and configurations of novel cellular substrates to match the increasing performance requirements of the upcoming generation of EATs.

Figure: examples of periodic cellular structures fabricated by investment casting (University of Salento) and by SEBM (University of Erlangen-Nürnberg)

Team Involved

Principal Investigator: Prof. Enrico Tronconi

Tommaso Selleri, PhD: member of BEATRICS from 16/11/2018 to 15/12/2019

Matteo Ambrosetti: member of BEATRICS from 11/01/2021