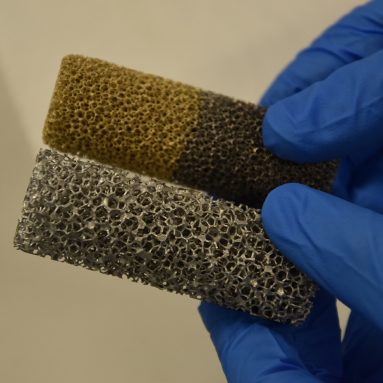

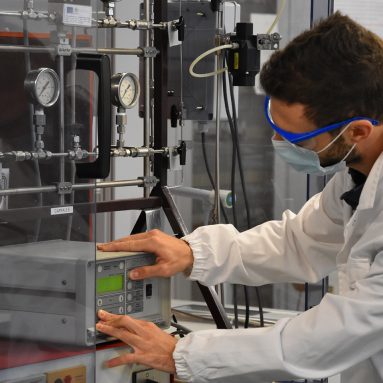

To this purpose we combine CFD modelling with lab-scale experimentation in order to identify the optimal structure-performance relation of existing and novel substrates, use such new knowledge to design optimized prototypes, apply additive manufacturing technologies for their production, and construct a semi-pilot tubular reactor to test them at a representative scale.

The project results will enable novel reactor designs based on tuning geometry, materials and configurations of the conductive internals to match the activity – selectivity demands of specific process applications, while impacting also other research areas.

The new reactor technology will have significant influence on both the Energy and on the Environment scenarios. Just as an example, it will enable compact Gas-to-Liquids process technologies with potential to drastically reduce flaring of associated and remote Natural Gas.